Innovative crimping technology revolutionizes manufacturing

A major advancement in manufacturing has resulted in a new crimping technology that promises to improve efficiency and precision across a wide range of applications. Developed by a team of engineers at TechSolutions Inc., this innovative approach aims to change the way components are connected in industries ranging from automotive to aerospace.

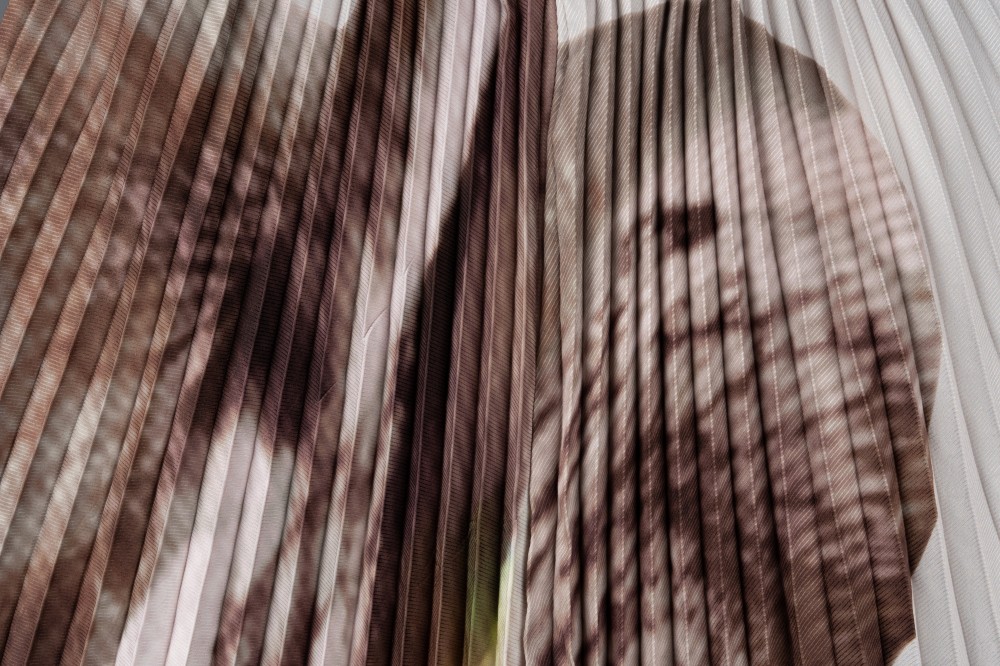

Crimp technology involves a specialized process that securely joins two materials without the need for additional fasteners or adhesives. By utilizing advanced mechanics and precise calibration, the new method ensures a consistent and reliable connection, reducing the risk of failure in critical applications. This is especially important in industries where safety and durability are paramount.

One of the standout features of this crimping technology is its adaptability. It can be applied to a wide range of materials, including metals, plastics and composites, making it a versatile solution for manufacturers. In addition, the process is designed to minimize waste, in line with the growing demand for sustainable manufacturing practices. By reducing the use of excess material, companies can reduce production costs while also contributing to environmental protection.

Early adopters of the technology report significant improvements in production speed and product quality. For example, an automotive manufacturer integrated the new crimping method into its assembly line and saw a 30% reduction in assembly time and a significant reduction in product defects. This not only increased productivity, but also improved customer satisfaction.

The launch of this innovative crimping technology highlights the importance of adopting new technologies as the manufacturing landscape continues to evolve. Industry experts believe that as more companies adopt this approach, it could lead to a paradigm shift in the way products are designed and assembled, ultimately driving efficiency and innovation across the industry.

In summary, the new crimping technology represents a promising development in the manufacturing industry that blends efficiency, adaptability, and sustainability to redefine industry standards.